“We will create powerful and productive partnerships with our suppliers.”

Onshore? Offshore? Some of each?

Made in Iowa

AERON Advanced Manufacturing, LLC is our flagship 74,000 square foot plant in Mason City, Iowa.

Starting with a few plastic injection presses and manual assembly lines in 2008, AERON has brought the “Advanced” to manufacturing in Iowa with a significant (and ongoing) investment in people, machinery and upgrades to the facility. Now, AAM can handle a wide variety of injection, automated assembly, fragrance filling and packaging demands.

“Made in Iowa” is ideal for seasonal or trendy items that can benefit from short lead times and quick turn-around. The warehouse provides pick-and-pack and bulk distribution. This plant is also ground-zero for AERON’s intensive R&D activities.

Partnering with Chinese Manufacturers

AERON has been manufacturing in Asia for two decades. Our two partner factories in Guangdong Province, China, were both founded to meet our production requirements, and have grown along with AERON. Our team in China includes dedicated sourcing agents, quality control managers, and designers, as well as our VP of Asian Operations.

Products that require intricate electronic assembly and complex deco processes are well suited for Asian manufacture, and over the years we have developed an extensive network of specialty sub-suppliers specializing in everything from vac-plating to specialty LED lighting.

Growing in Mexico

Combining the strengths of our Iowa and Texas plants with low-cost component manufacturing and deco processes in Mexico, AERON has created a winning formula for domestic production and speed-to-market.

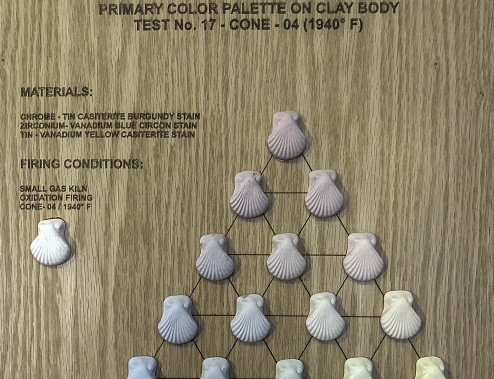

Bottle manufacturing, stamped metal, rubberized coating and electroplating are among the many industrial services that feed from Mexico into our US production stream. In addition, we work with artisan ceramic shops to develop materials that hold and diffuse fragrance in beautiful new ways.